Stone plastic composite boards are the most innovative high-tech flooring materials in the world's building materials industry, considered as the revolutionary international technology of the 21st century. Not only are they environmentally friendly, fashionable, beautiful, and comfortable, but their cost and price are relatively stable. The appearance and natural stripes of stone plastic flooring showcase the original wood style, making home decoration more personalized.

1. Advantages of Stone Plastic Decorative Materials

As a new favorite in the building materials industry, stone plastic composite boards have many advantages:

(1) Green environmental protection. The main material is natural stone powder (calcium carbonate), which is widely available and inexpensive. It does not contain formaldehyde or any toxic and harmless substances, has no radioactive pollution, and is environmentally friendly, belonging to green environmental protection products.

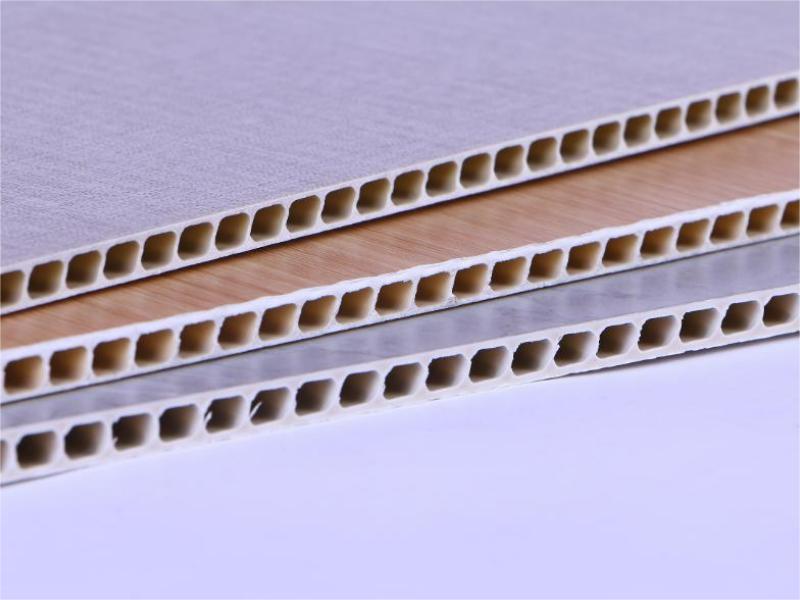

(2) Super strong and lightweight, with flexible dimensions. Stone plastic boards have a thickness of only 2-3mm per square meter and a weight of only 2-3kg, which is less than 10% of ordinary flooring materials. In high-rise buildings, it has an unparalleled advantage in terms of building load-bearing and space saving. As an artificial whole synthetic product, it can adjust the product process and formula at will according to usage requirements, thus producing materials with different properties and shapes, with a material utilization rate close to 100%.

(3) Durable and easy to maintain. The service life of stone plastic boards is usually over 50 years, waterproof and moisture-proof, wear-resistant and anti-slip, insulating and flame-retardant, with high safety, easy to install and maintain, and easy to replace.

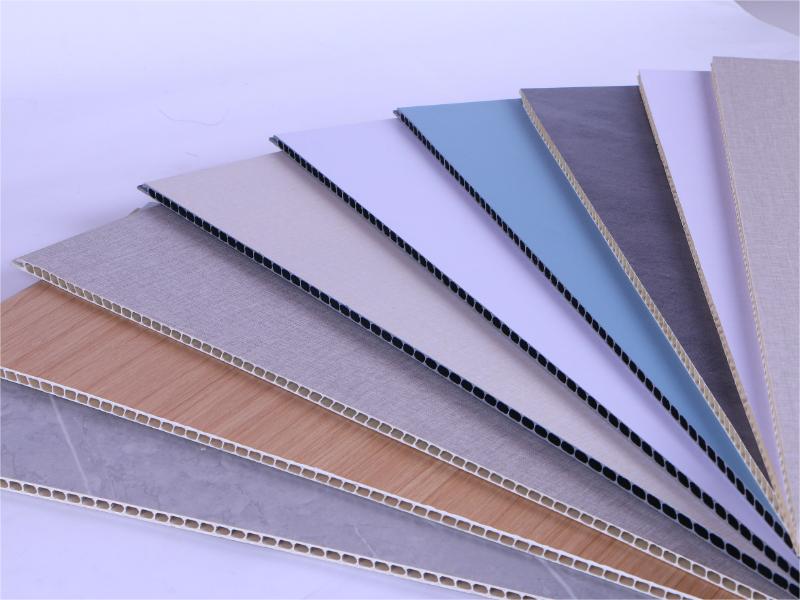

(4) Novel colors, with a variety of colors to choose from, vibrant colors, natural and realistic, with free combination of color patterns, highlighting personal colors.

Development trends of stone plastic composite materials

(1) In the field of molding and processing. Extrusion molding technology is the mainstream method for the molding and processing of stone plastic composite products, mainly used for the development of profiles, pipes, plates, etc. With the diversification of stone plastic products and the complexity of the application environment, higher requirements have been put forward for the extrusion process. At the same time, it is also necessary to study the application of injection molding technology in the processing of stone plastic products for specialized components.

(2) In terms of material properties. With the industrialization of stone plastic composite materials, researchers have discovered the defects of stone plastic composite materials, and users have put forward higher requirements: for garden landscape outdoor products, aging resistance and color fading prevention, and extension of service life are required; for indoor windows, doors, and decorative materials, good flame retardant properties are required; for load-bearing stone plastic products for building foundations, high mechanical properties are required, and reinforcement and improvement of creep resistance are needed. With the increasing call for energy conservation, the construction industry also puts forward higher requirements for the energy-saving effect of stone plastic composite materials. Therefore, stone plastic composite materials are developing towards functionalization and high added value.

(3) In terms of energy conservation and environmental protection. Product safety and energy conservation and environmental protection are becoming increasingly popular. Consumers' demand for products is no longer limited to basic functions, but also requires products to be safe for users and friendly to the natural environment. Promoting and popularizing new environmentally friendly stone plastic flooring is conducive to reducing energy consumption and helping to build an energy-saving society. New environmentally friendly stone plastic flooring has the advantages of thermal conductivity and heat diffusion speed that cannot be compared with traditional floor materials (marble, tiles, solid wood flooring, engineered flooring, etc.), which can effectively reduce the unit heating energy consumption of families.

Post time: Apr-12-2025